Slop Oil Turns Into Profit

“Slop oil” or “oily sludge” are waste oil and sludge produced in both upstream and downstream processes.

Many of these resources contain a high percentage of oil that can be recovered as valuable products; the economic and environmental contribution of reduced waste volumes should not be overlooked. This trash is costly to dispose of for the oil industry because it is both environmentally harmful and difficult to transport. Due to this, there is a great need for services that can effectively handle oily sludge. Slop oil treatment additionally adds value by recovering hydrocarbons that would otherwise be lost.

Main advantages

- Eco-friendly way as an alternative to the expensive disposal of slop oil

- Creation of value through the 80 to 95% recovery of saleable hydrocarbons

- Decrease in overall disposal costs

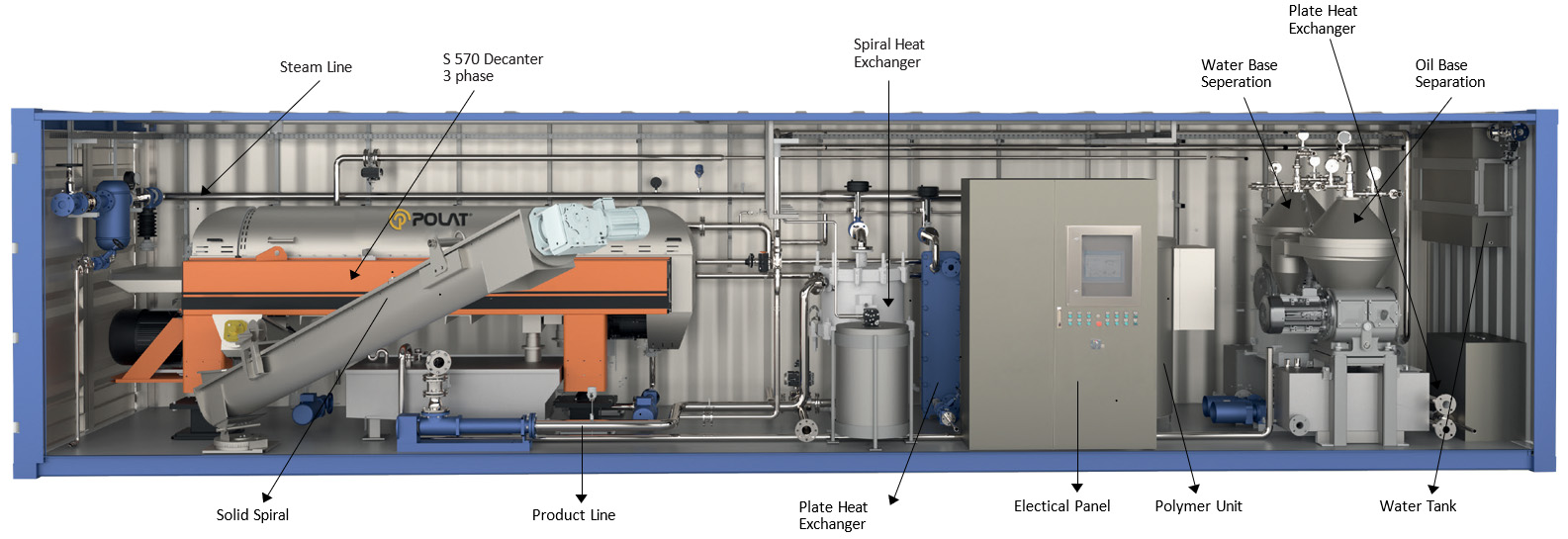

Oxint CRU

Solution for Slop Oil Recovery

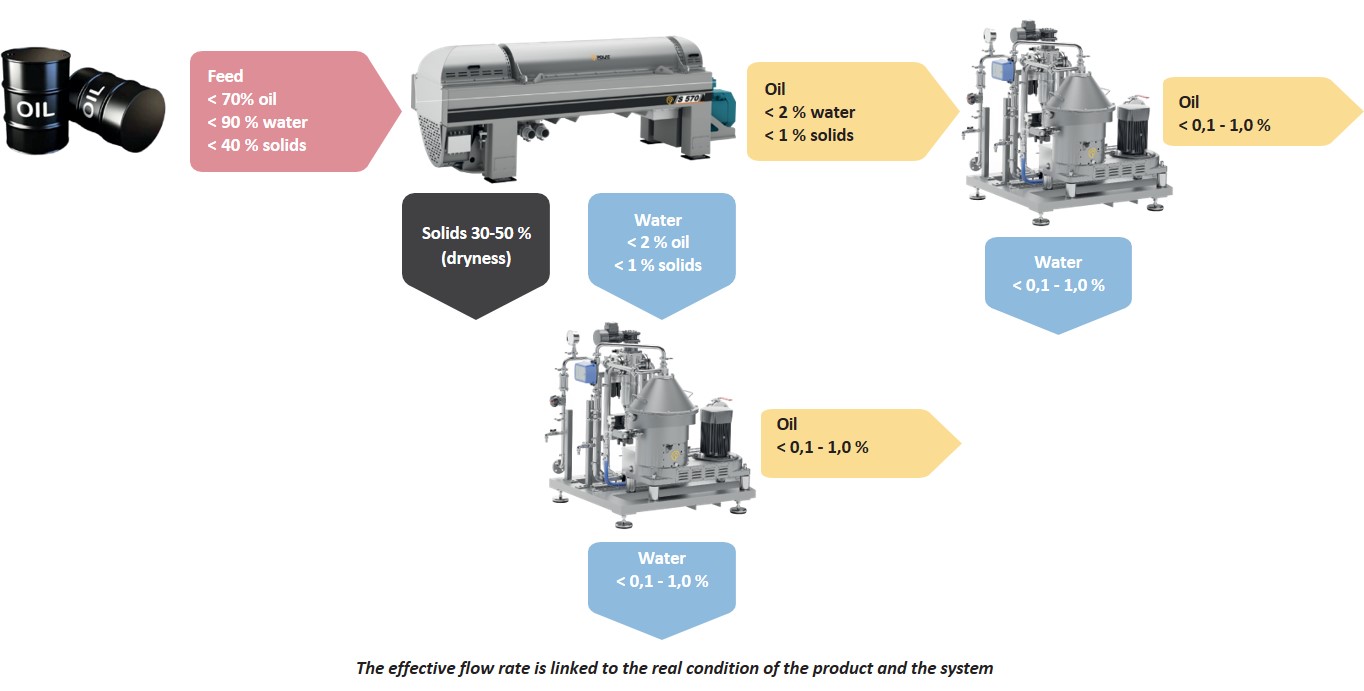

Unique process solutions

2-stage treatment

3-stage treatment

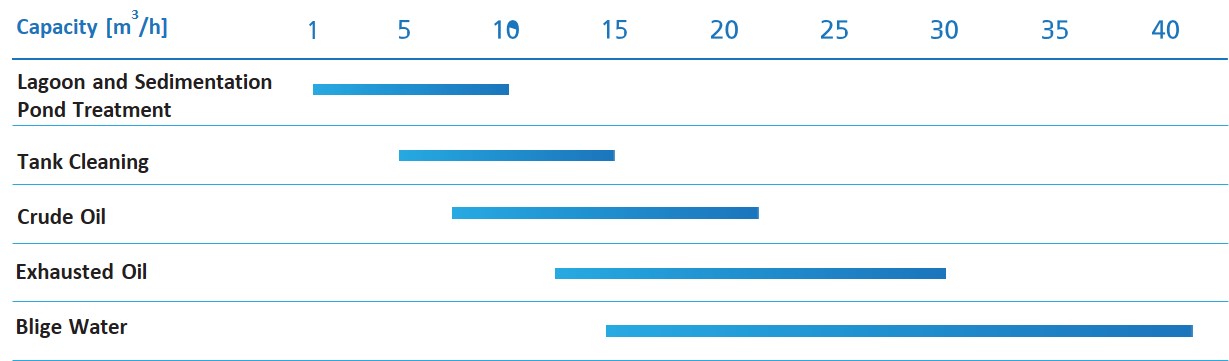

Some specific sectors of origin of slop oil:

- Tank bottoms

- Marpol sludge

- Desalter of spec products

- Bottom sediments from API separators

- Lagoons and oil pits

- Oily sludge from DAF units

The Cow System

Crude oil washing (COW) is a system whereby oil tanks on a tanker are cleaned out between voyages not with water, but with crude oil – the cargo itself. The solvent action of the crude oil makes the cleaning process far more effective than when water is used. (There is usually a final water rinse but the amount of water involved is very low.) The system helps prevent pollution of the seas from operational measures.

Crude oil washing was made mandatory for new tankers by the 1978 Protocol to the MARPOL Convention. Regulation 33 of MARPOL Annex I requires every new crude oil tanker of 20,000 tons deadweight and above to be fitted with a cargo tank cleaning system using crude oil washing.

Regulation 33 states that COW installation and arrangements should comply with at least all of the provisions of the Specifications for the Design, Operation and Control of Crude Oil Washing Systems adopted by IMO in 1978, as may be revised.

In 1999, IMO adopted revised specifications for COW by resolution A. 897(21) Amendments to the revised Specifications for the Design, Operation and Control of Crude Oil Washing Systems (Resolution A.446(XI), as amended by resolution A.497(XII).

Do you want to give value to your production scrap?

We help you identify and implement alternative solutions, more advantageous from an economic point of view and more respectful of the environment for the recovery of scraps. Contact us for more information.

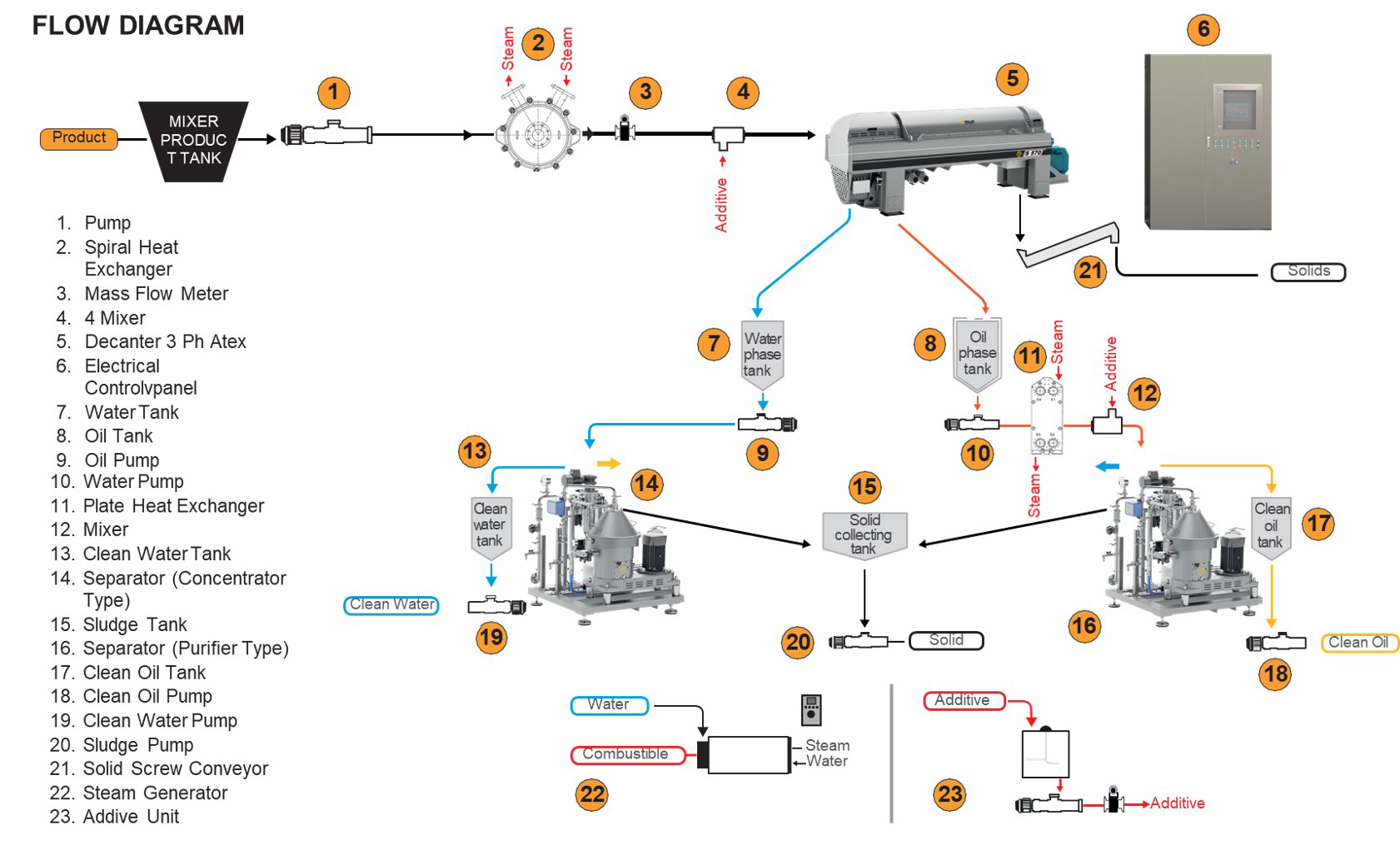

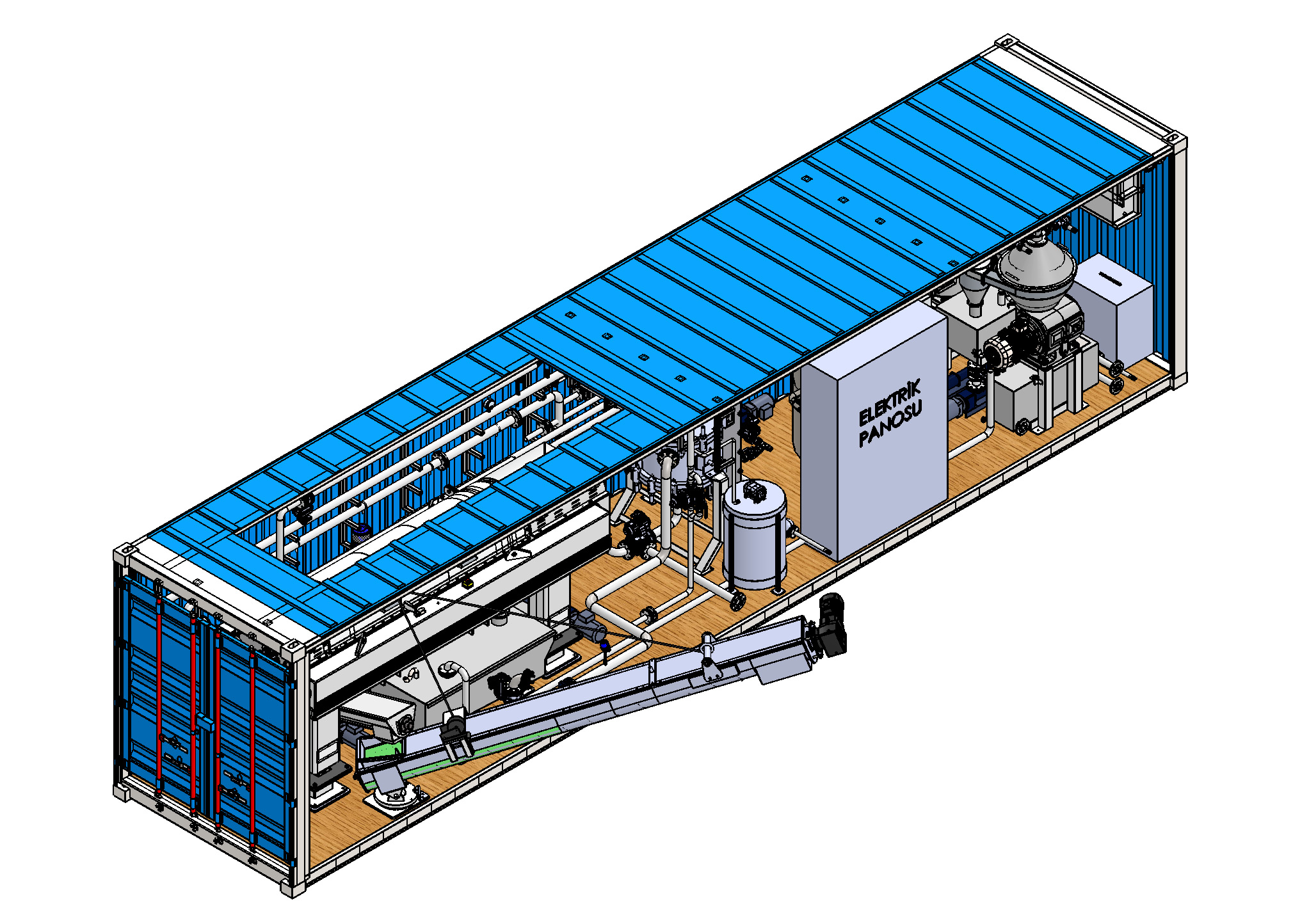

All-in-one solution with Oxint and Polat Makina technology

The Oxint R&D Center assists in the creation of innovative processes on specific customer request or in accordance with our market research. Attraverso una serie di test pilota interni, valutazioni di laboratorio e valutazioni di macchine o prototipi in loco, le nostre soluzioni creative vengono continuamente testate e convalidate. Solo allora vengono resi disponibili per il mercato.

- Competenza e responsabilità inequivocabile

- Comunicazione e pianificazione affidabili

- Configurazione ottimale dell’impianto e del processo senza barriere

- Elevato grado di funzionalità e affidabilità degli investimenti

- Processi in sicurezza

- Soluzione mobile

- Unità di dosaggio e stazioni di servizio

- Riscaldamento e pompaggio

- Sistema completamente controllabile

- Pretrattamento

- Progettazione per aree pericolose